Passports lack chips – Business – Kommersant

[ad_1]

Russia has suspended the issuance of new passports. Goznak attributes the problem to the fact that Zelenograd Mikron does not have time to produce the required number of microchips on time. Interruptions may indicate a systemic problem for Russian factories, because of the sanctions they are forced to look for alternative materials and components, the testing of which stretches for weeks, market participants and experts explain. In their opinion, the volatility of production will remain until full import substitution, which will take years.

Portal “Gosuslugi” today suspended the acceptance of applications for the issuance of new passports (the so-called biometric passports, issued for ten years and contain a microchip), without explaining the reasons.

Passports are issued by the state Goznak, on the website of which the situation explained chip shortage. “In recent months, there has been an increased volume of applications for the personalization of foreign passports, thereby significantly increasing the need for microcircuits that are built into the passport blank,” the report says.

Microchip manufacturer Mikron, according to Goznak, is “reconfiguring equipment and optimizing processes to meet increased demand in the future.”

Goznak expects that the production of international passports will be restored within a month. In Mintsifra “Kommersant” did not respond.

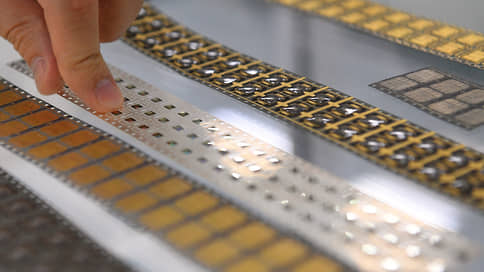

The international passports of the new sample contain chips with a topological norm of 180 nm. They are produced by Mikron JSC (owned by Element Group of Rostec and AFK Sistema). Its capacity is 3 thousand plates per month. If we assume that Mikron will load all the capacities for the production of only chips for biometric passports, they, under conditions of ideal operation of production lines and the availability of all consumables, can be made 6 million pieces. But the company produces chips of different topological standards. For example, about 60 thousand chips for bank cards and biometric passports fit on one plate – 2 thousand pieces.

Potentially, the release of similar processors can be started by NM-Tech, which received most of the property of the bankrupt Angstrem-T. In October 2022, the Ministry of Industry and Trade informedthat Mikron specialists will help launch production at this enterprise, but it is not known whether this happened. The remaining Russian factories produce microelectronics in thicker topologies, from 350 nm.

In a number of regions, problems with obtaining new passports appeared last week. So, on January 27, residents of Tver were told that the extradition postponed until mid March. A similar situation has developed in Orsk, Blagoveshchensk, and Kamchatka. One of the Gosuslug users in the Orenburg region was told that paperwork had been suspended “until the second half of March,” RIA Novosti reported. Similar problems arose in August 2022, when documents stopped issuing in Russian diplomatic missions abroad. The Russian Foreign Ministry then spoke about the need to “reformat the electronic media.” In September 2022, the issuance of biometric passports resumed.

Mikron confirmed that the company “faced the need to adjust the schedules for the production and supply of electronic components with a multiple increase in the number and volume of customers,” adding that the company is now working “in an enhanced mode.”

The Ministry of Industry and Trade assured Kommersant that production did not stop, shipments were underway, Mikron was increasing volumes: “We are in constant contact with the management of enterprises, receive feedback from them and, if necessary, provide all the necessary support.”

Stopping the issuance of biometric passports is “a special case that illustrates a systemic problem related to the fact that the supply of materials necessary for the production of microelectronics, including silicon and chemistry, as well as acids and photoresists, is unstable,” says a Kommersant source close to one of the component suppliers. He adds that enterprises are also experiencing a shortage of spare parts for equipment, the purchase of which is extremely complicated due to sanctions.

Russian semiconductor plants will continue to periodically suspend production in the future, a Kommersant interlocutor close to the Ministry of Industry and Trade believes: “The instability in the supply of photoresists and other chemistry leads to the fact that enterprises, when switching to new materials, are forced to stop production lines and conduct testing in order to prevent breakage expensive and scarce equipment. Testing usually lasts at least a few weeks, production during this period is not possible. The director of the Basis consortium, Arseniy Brykin, notes that the solution to the problem will be either the lifting of sanctions or the launch of production in Russia of the maximum possible number of high-purity materials and substances, which will take at least several years.

[ad_2]

Source link